News

HONYLITE Exported Stainless Steel Honeycomb Disc-Shaped Flow Conditioner to UNITED STATES OF AMERICA

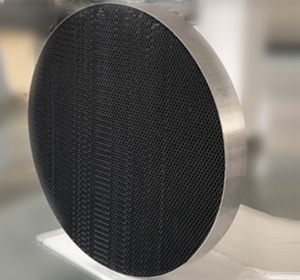

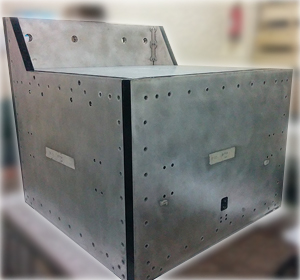

HONYLITE successfully exported large diameter Flow Conditioner of Stainless Steel Honeycomb for Wind Tunnel to United States of America in October 2020.

This disc-shaped Flow Conditioner is horizontally situated in a vertical downdraft reactor vessel, so flow would be vertical and this relatively thin flow conditioner would sit like a pancake. Pressure is around 8.5 atm. with flow velocity around 2.0 m/s. Max temperature of the flow is 250 °C with the reactor catalyst surface temperature inside this vessel is 900 °C. We use advanced manufacturing technology to ensure high technical standards and international quality requirements of flow straightener/conditioner.

DEFEXPO 2020

HONYLITE made its presence at the DEFEXPO India, Feb 2020. DEEXPO India is the largest showcase for new and future defense technology and it is the largest exhibition for the world’s defense companies to display their land, sea and air capabilities at a single exhibition. HONYLITE showcased itself as one of the leading Defense related Honeycomb Panels manufacturer in India.

DUBAI BIG-5

HONYLITE made its presence at The Big 5 Show 25th – 28th November 2019 at Dubai. The Big 5 Show has been the go-to international trade fair for building and construction industry professionals looking towards glimpsing the future and position themselves in the competitive markets in the Middle East. At the Big-5 show HONYLITE made its strong reputation as a promising Honeycomb Panel supplier with timely delivery and best quality.

HONYLITE Exported Honeycomb Panels for ABU DHABI Bus Shelters

The impact of bus shelters on the urban environment of large cities can be significant. HONYLITE had successfully supplied Aluminum Honeycomb Panels for construction of bus shelters at Abu Dhabi. We were appreciated for the timely delivery and good quality supply by our client. And not just that our team personally visited the site at Abu Dabi to witness our piece of work getting converted to final Bus Shelters.

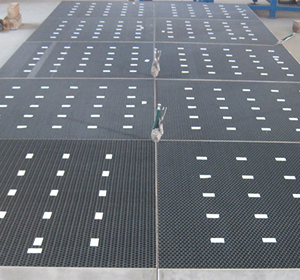

HONYLITE Exported Stainless Steel Honeycomb Modules for Wind Tunnel to SOUTH KOREA

HONYLITE successfully exported odd sized 30 Modules of Stainless Steel Honeycomb for 6.25 x 6.25 mtrs. Wind Tunnels to South Korea in October 2019.

HONYLITE Honeycomb Flow Straightener is an important device for flow field testing and analysis of cutting-edge technology innovations. We use advanced manufacturing technology to ensure high technical standards and international quality requirements of flow straightener. These Flow Straighteners are not only light in weight and has high strength but it also has high straightness throughout the honeycomb.

KAZBUILD ALMATY

We had participated at the KazBuild Exhibition which took place at Almaty from 04th-06th September 2019 and we received a very warm response from the visitors out there. As a feedback from the customer visit we got enlightened with the fact that our product “Honeycomb Panels” could be a good replacement for many of the orthodox panels used in the Construction and Railway Industry.

We were very obliged with the Indian Embassy at Kazakhstan helping us to get in touch with some of the prime customers in Construction Industry at Kazakhstan.

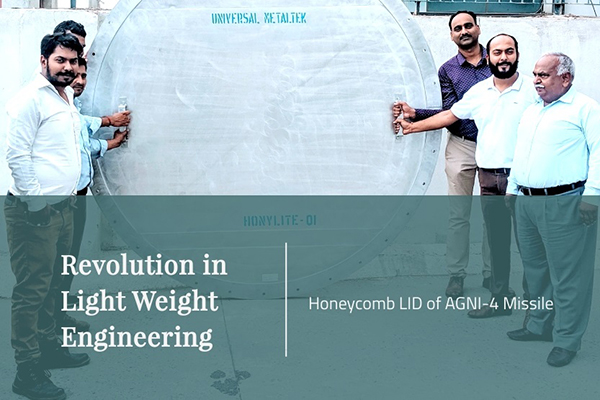

HONYLITE supplied Honeycomb LID of AGNI-4 Missile to ASL

Advanced Systems Laboratory (ASL) is a DRDO laboratory located in Hyderabad. Since inception of our organization under Brand Name HONYLITE, we are working with various types of honeycomb cores and panels including Aluminum & Stainless Steel. We have become major exporter of this product with exporting to around 34 countries and developed indigenously as an endeavor in this field.

Recently we manufactured Honeycomb LID of AGNI-4 Missile with developed version. The earlier version of the product was manufactured using Aluminum thick plates, which was too heavy to handle by the Indian Armed Forces, which was weighing 300 Kgs approximately to the best of our knowledge. But now it has been developed with reduced weight of only 52 Kgs with ultimate accuracy using Aluminum Honeycomb sandwich structure. The new design developed by us was very intrinsic and done to the level of end users’ ultimate satisfaction. These all successes have been only possible due to the all out free hand support of our Founder – Mr. Bal Krishan, from the back drop of working culture of our organization.

Lightweight Panels New Product Innovation Leadership Award.

05 October 2017

On 05th October, 2017 at ITC Maratha, Mumbai, Universal Metaltek which is part of Honylite Group was the recipient of Frost and Sullivan’s 2017 India – Lightweight Panels New Product Innovation Leadership Award.

Frost & Sullivan Best Practices Awards is a Global program that recognizes outstanding industry achievements by companies globally. The methodology for determining Award recipients is unique – a deep dive research and analysis conducted by Frost & Sullivan industry experts, with winners being identified using structured metrics based evaluation process.

HONYLITE supplied Stainless Steel Honeycomb for Wind Tunnel to IIT KANPUR

HONYLITE successfully supplied a very odd sized 2500 x 2500mm Stainless Steel Honeycomb Module in single piece for Wind Tunnels to IIT Kanpur Aerospace Department in July 2017.

HONYLITE Stainless Steel Honeycomb Module is used to reduce turbulence levels in Transonic & Supersonic Wind Tunnels. With hexagonal cell diameters starting at 0.8mm till 42mm, we are able to produce Homogeneous structures with the depth of 450mm. Pitch & Yaw Angularity HONYLITE supplied Honeycomb panels for making Honeycomb Deck of a satellite to RCI in July 2015.

Nowadays many space companies, often use honeycomb sandwich panels as part of the primary and secondary structures of the small satellites they develop. Although honeycomb panels have been used for the past 50 years gaining a better understanding of these sandwich structures, and the methods and solutions used to produce structural assemblies from them is a major revolution in the aerospace industry.

HONYLITE supplied Honeycomb Deck to RCI

Research Centre Imarat (RCI) is a DRDO laboratory located in Hyderabad. The lab is responsible for Research and Development of Missile Systems, Guided Weapons and advanced Avionics for Indian Armed Forces.[2] It was established by APJ Abdul Kalam in 1988.

HONYLITE supplied Honeycomb panels for making Honeycomb Deck of a satellite to RCI in July 2015.

Nowadays many space companies, often use honeycomb sandwich panels as part of the primary and secondary structures of the small satellites they develop. Although honeycomb panels have been used for the past 50 years gaining a better understanding of these sandwich structures, and the methods and solutions used to produce structural assemblies from them is a major revolution in the aerospace industry.

HONYLITE Honeycomb Panel used to construct BMW i8 booth

The BMW i8, first introduced as the BMW Concept Vision Efficient Dynamics, is a plug-in hybrid sports car developed by BMW. The BMW stand is characterised by the new track in the form of an infinity symbol symbolising the sustainable mobility concept of BMW.

Visitors walk along the long straight stretch of the track and experience the new world of electric vehicles from BMW. HONYLITE Honeycomb Panels has been used to construct the floor and wall panels of the entire booth along with the display fixtures.

HONYLITE supplied Honeycomb Deck to Team Indus for Google Lunar XPrize

Team Indus is an aerospace start-up. They are involved in designing and developing Lander and Rover for a mission to the Moon as a part of a global competition Google Lunar X Prize (GLXP). The competition encourages privately funded enterprises worldwide to explore the Moon and prove their capabilities.

The main objectives of the competition are to softly land a spacecraft on to the Moon’s surface, deploy a rover that will traverse a minimum distance of 500m and capture panoramic photographs, videos and transmit data back to the Earth. HONYLITE supplied Team Indus the complete fabricated Honeycomb Deck using aerospace grade aluminum honeycomb panels in a very short span of just 16 days.

INDIA COMPOSITE SHOW 2013

HONYLITE are pleased to announce that they will be attending Composites Europe this year, from 24th – 26th October. Shivam Agarwal says “We have invested a considerable amount of energy into servicing the commercial sectors and have built our reputation on supplying aluminum honeycomb to all the major industries; Rail, Marine, Defense, Automotive and Construction and continue to do so.

Composite technology in these sectors is booming and demand for Aluminium Honeycomb is increasing. We would be happy to hear from and assist any customer with the design and development of any product, which has the potential to use aluminum honeycomb.”

INTERNATIONAL RAILWAY EQUIPMENT EXHIBITION 2013

HONYLITE exhibited for the first time at International Railway Equipment Exhibition 2013 from 03rd – 05th October. Having a strong international focus, HONYLITE has established a large network of customers worldwide. Working with HONYLITE means to be in professional hands, receive an excellent customer service, together with a high quality product offered on short lead times.

HONYLITE have recently expanded their production capacity in order to facilitate an increase in customer demand. This increase in production capacity will also offer the potential for HONYLITE to gain new customers.

INDIA COMPOSITE SHOW 2012

HONYLITE exhibited at India Composite Show, held at New Delhi from 01st – 03rd November. This annual show is attended by thousands of designers, engineers and other specialists, and marks an important date in the diary for professionals working within the composites industry.

HONYLITE will have a range of aluminum honeycomb on display, and will be welcoming new and existing customers to its stand to discuss how the honeycomb can be used in different applications.